It's Never Been Easier to Make Your Product a Reality

I've invented, produced, and sold multiple products at minimal upfront expense. How you can do it too; why you should go for it RIGHT NOW.

I talked to a friend of mine today, who you may know as Pocket83. He told me about a board game that he’s been working on for a decade that he considers to be very good. However, he’s been hesitant to release it per copyright, production, and a host of other reasons.

In other words, he wants all his ducks 🦆 in a row. While admirable, you can also go to far and simply never finish your project.1 Perhaps this tendency toward perfection versus very good (or even acceptable) becomes more prominent the more you cherish something. However, at some point you just have to go for it.

The good news is that it’s never been easier to make your idea a reality. Read on to see how YOU can make and sell your invention. In this article I cover:

How to produce something

How to sell it

Caveats (i.e. it’s easier but it’s still not easy)!

Step 1: How to Get Things Made

Cutting right to the chase: Three things/services that enable (me) the garage artisan to make something for the masses. And by “masses,” I mean the 10s, the 100s, even the 1000s.

Digital manufacturing (3D printing & laser cutting)

A decade ago (maybe two) if you wanted to make something physical to sell you had ~two options: Make everything yourself (or pay someone to do so by hand), or set up mass manufacturing at a very high initial price, with the hope that a low unit-price-at-scale would eventually turn into a sizable profit.

Today you can get a very good 3D-printer for around $1000 from Prusa or Bambu. Model your thing, prepare prints, send them to your device. Bada bing, bada boom, out pops your product2. The flip side is that printers3 are inexpensive for everyone else too, meaning increased competition. Laser cutters are another option, but take a bit more setup to get working. Once functional, they can turn out parts very fast.

Another option is on-demand production services. This can be local 3D-printing people or laser aficionados, as well as more formalized on-demand services that can cost-effectively make things at low prices. At least two of the board houses listed below also offer 3D-printing and other fabrication services that you can consider–as you scale up into the realm of moderate success.

Cost-effective, on-demand electronics production (and more)

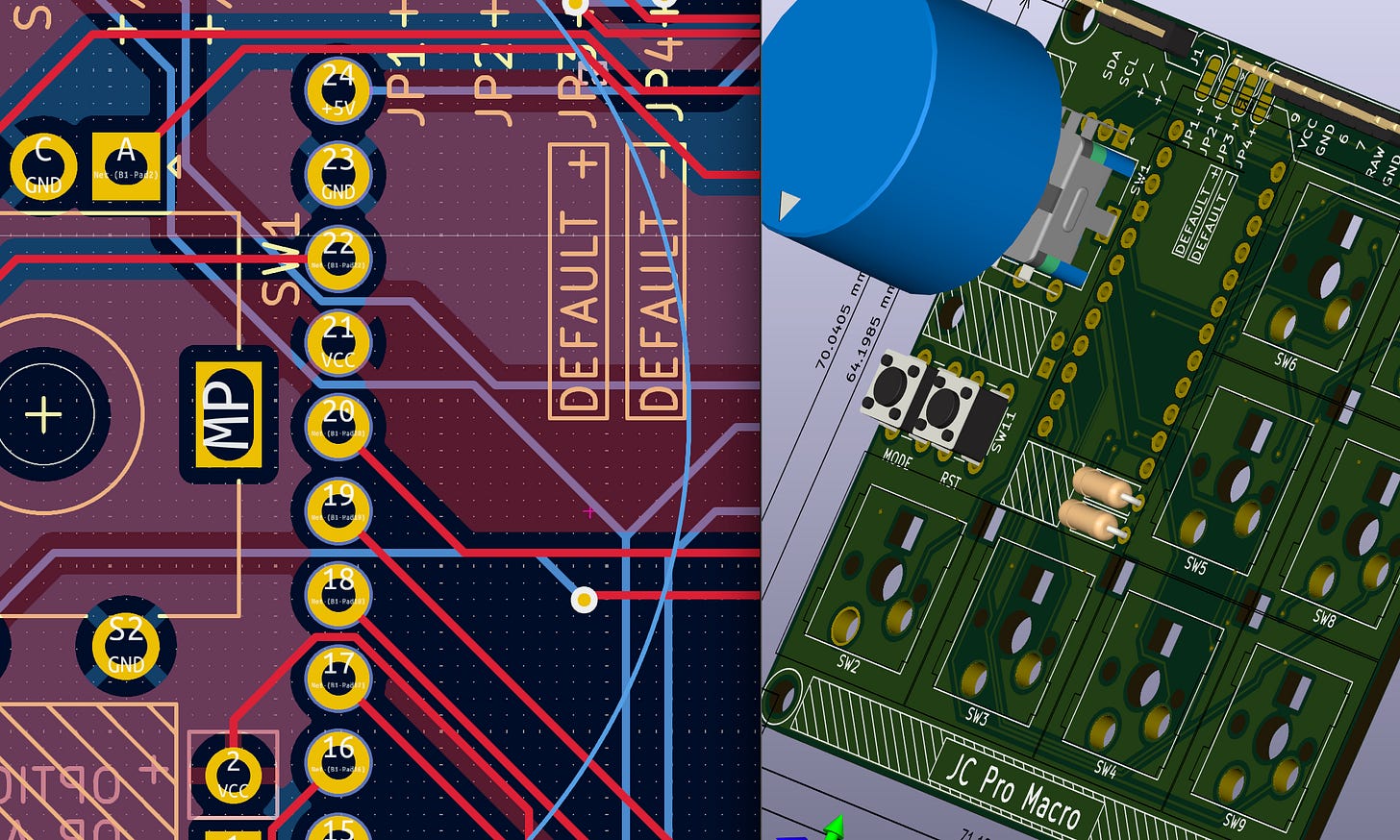

If you want to build something electronic, this typically means amalgamating a handful of chips to perform specific functions via a printed circuit board (PCBs). Design your circuit (in an EDA program like KiCad) send files to the board manufacturer, and you can have actual PCBs in your hands in about a week, often at prices under $50 including shipping.4

These board houses can also typically handle sourcing and assembly components–PCB assembly, i.e. PCBA–which I would recommend for anything more than the most meagerly production quantities.

Put it all together: careful Design, contract manufacturing

If you don’t want to do the final assembly yourself, you could get a contract manufacturer to put things together for you.5 You might consider somewhere like Cyber City Circuits. Alternatively, inquire with a local machine shop to see what they offer, or if they “know a guy.”

Contract manufacturing can then take care of some/much/all of your fulfillment process, but expect to pay for it. It’s especially important that you set your prices high enough to make a profit, and to make your design as easy to put together. Consider this expense early in the process to ensure profitability.

If you’re going to self-final-assemble, consider your time to be just as – if not more –valuable than a contract manufacturer. If you make a profit, but not enough of a profit, it’s generally easier to get a job at McDonalds. And you get free fries.6

Step 2: Actually Sell Your Thing 💰

Crowdfunding: Promotion + Funding + Market Research

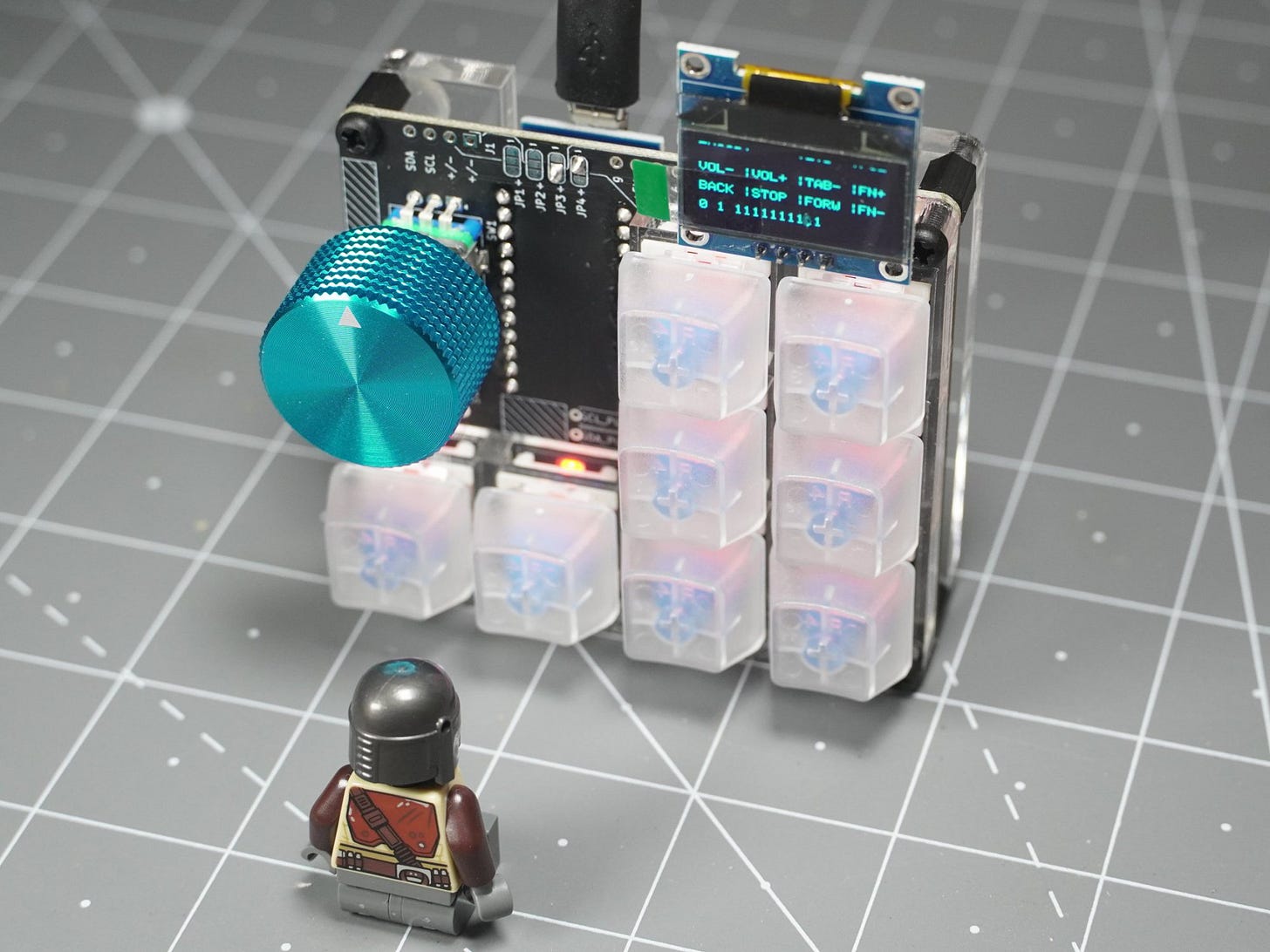

Several years ago, I came up with a product called the JC Pro Macro 2. It’s an 8-key mechanical macro keypad with a rotary encoder that can be programmed to do all kinds of fun stuff like adjust computer volume and fast-forward through YouTube videos. GPIO pins are also broken out, allowing one to turn on a fan or other hijinks.

Long story short, I created a Kickstarter crowdfunding campaign for it that accomplished the following:

Confirm the market exists. People committed real, actual money.

Kickstarter helped promote my project there, and (eventually) via my storefront on Tindie. This also established me, Jeremy Cook, as the creator of this particular gadget – if not legally, in the general Internet zeitgeist.

Orders in-hand (and funded) allowed for immediate semi-mass production, saving money and effort versus per-piece production.

**Crowdfunding Danger, Danger ⚠️**

It is bad form to not ship promised crowdfunding rewards, but if you set your prices too low you won’t make a profit. In this case you’re in a particularly bad spot because you’ve already ~sold a significant quantity of X at unprofitable price Y. Calculate out every little thing before you put a crowdfunding project up or success my be worse than failure.

Other Ways to Sell

I’ve had success with Kickstarter, and I’ve had success with Tindie. Other sites, such as eBay, Etsy, and Amazon may give you access to a larger market, but, for better or worse, I have little experience with them.

Reverb is also an interesting option for musical-themed devices. I sold a few of my Lightstrum light-up picks there. You can also design your own e-commerce site, which has its own set of advantages and disadvantages

Perhaps it’s a good idea to sell something that you’ve made before taking the leap into crowdfunding. Here’s an article I wrote some time ago contrasting these two options, and another with crowdfunding tips if you want to go that route.

Required Skills, Learnings, and Caveats

As with any pursuit, consider your skills and limitations. I’ve been designing circuit boards for around five years and am just now to the point where I would consider myself competent enough to take on such a job for someone else. I’ve also been involved in engineering and making things for much longer. So…

Caveat A: Do I, Jeremy Cook, Have an Unrealistic Advantage?

While what I’ve written makes sense (to me) I should be realistic in the fact that not everyone shares my background. I have built up skills and digital manufacturing tools (e.g. 3D-printer, laser cutter), and have experience with build-to-spec manufacturing services, most notably involving printed circuit boards. I also know a lot of people who know a lot of things that I don’t know (yet).

On the other hand, I didn’t always have access to these resources, and there’s no better time to start developing your skills than now. Alternatively, if you have a great idea, but won’t have the skills in a reasonable amount of time, you can also pay the right person or service to help. Feel free to reach out (hi at jeremyscook.com) if you want to bounce an idea or two around. Maybe I could help, or at least point you in the right direction.

Caveat B: I haven’t gotten rich from these pursuits (yet) 💰

Between my JC Pro Macro 2 Kickstarter and sales of niche electronics on Tindie, I’ve sold around 1000 items. It’s public information that my Kickstarter grossed $16,607, and let’s just say that my other sales on Tindie are roughly equal that total. So $30,000 give or take since circa 2020. Divide by 5 years, and you’re left with $6000 per year gross.

Assuming a healthy profit margin, that does represent a decent chunk of change… if you’re not trying to make a living off of it. I also haven’t tracked the time I spent on these pursuits. Honestly am scared to do so.

At the same time, my primary income is writing about technology and the experiments that I do. Making and selling electronics helps make that possible. Finally, I’m driven to make things. I would be doing this in some form or fashion whether I got paid for it or not.

But DO I REALLY Have an Advantage?

It’s possible that my making abilities (and risk aversion) means that I restrict my pursuits to things that I can accomplish myself. A real home run might mean hiring someone(s) to to the circuit board and mechanical design, paying them, producing XXX of widget YYY and profiting on the difference between sales vs production and design expense.

Maybe I’ll try the product manager role at some point. However, I do genuinely enjoy designing products myself, and even putting them together (though there is a limit). As outlined here, if you have an idea, you can make it a reality. It’s an amazing feeling when someone sees your thing as useful/cool enough to pay real, actual money for it. This feeling, in addition to the real, actual money that you receive, plus a potential knowledge/reputation boost can make selling products well worth it.

All that being said, if you have an idea, I say go for it right now!

Thanks for reading. If you enjoyed this post and want to get more in your inbox, sign up below:

Note that any Amazon links are affiliate

Addendum/Footnotes:

To his credit, Pocket83 has made many, many interesting things.

An example of a vacuum holder that I designed and printed, though did not sell. Maybe I should have. There are also ways to sell or license your design that could be considered.

I say “printers” here, but mean 3D printers. There’s probably some parallel with when Gutenberg invented the (2D) printing press in the 1400s, or (much later) when the Internet made passing text-based media to the masses ~free. Should I make a print version of Tech Adjacent? LMK in the comments 🗞️

I’ve used manufacturers PCBWay and JLCPCB for their board manufacturing and assembly assembly services. I’ve also used NextPCB and OSHPark for PCBs-only. All of these companies have sponsored and/or given me deals on their manufacturing process–to put that out there–but literally all of them have done excellent work.

As of now, it seems that JCLPCB has the smoothest and most cost-effective experience, especially with their integrated components supplier LCSC. Notably, OSHPark is the only US-domestic/non-Chinese supplier on this list, which could be important depending on how politics shape up in the next few months/years. Favorable labor rates, exchange rates, and/or government meddling are likely factors into how such companies are able to provide unbelievably low prices. Take that as you may.

There’s nothing like hand-soldering and screwing your device together (hundreds of times) to help you consider what you could have done differently, and what is really adding value to the customer. OTOH, if something adds little value, but ups the product’s cool factor–or what customers envision doing with it–a feature might be worth including.

In the case of my JC Pro Macro 2, yes it had breakouts for GPIO control, but I doubt anyone used it, beyond perhaps my friend Pat Regan. At the same time, I bet a lot of people thought, “Oooo, that presents a lot of cool possibilities.” I bet that hypothetical project got pushed to the side most of the time.

I assume you get free fries… and maybe a McFlurry. Just don’t accept the Free Floor Fries, even if they are alliterative and fun to say. A little floor spice definitely does not make everything nice, especially if you know about it.*

*I once got on an elevator at Countryside Mall with my wife. ~four kids (not mine) that looked like they were on a middle school baseball team got on and promptly dropped some sort of cinnamon bun pastry. A kid then picked it up and ate it. Putting myself in the mind of middle school Jeremy, I can kind of understand the impulse. I’m hoping I would have at least wiped it off!

**My wife tells me this was actually at International Mall in Tampa, Florida. Really though, it could be any mall in the USA. How many elevator floor pastries are eaten at malls each year? It’s not zero. Let me know what you think in the comments. Bonus points if you’re a mall security guard.